Specification

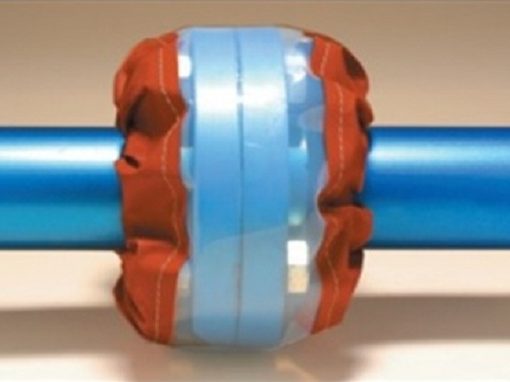

PVC safety shield

▷ Suitability for temperatures up to 60℃ and in the presence ofcertain chemicals, such

as concentrated acids,only at lower temperatures.

▷ Wide applications, particularly in conditions withambient temperatures and pressures

of 21 baror lower.

▷ Added benefit of a “See-Thru” feature, permitting easy visual inspection of pipe jointflanges,

valves and threaded connections.

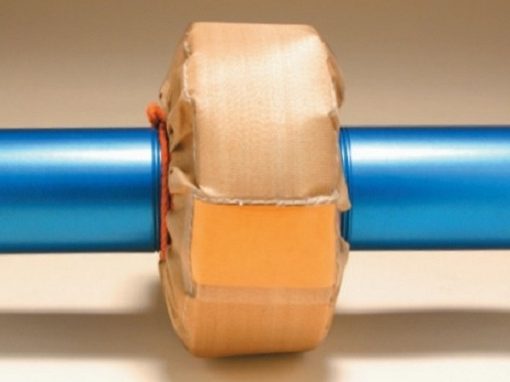

PPL safety shield

▷ Used to protect against hydrofluoric acid, a highly virulent chemical that is used to

etch glass and is also employed in petroleum cracking operations.

▷ Thermoplastic cloth demonstrates temperature and pressure resistance up to 225 ℃

and 76 bar.

▷ at sulfuric acid concentrations of 30% or less, are recommended up to line

temperatures of 93 ℃

TEFLON safety shield

▷ Demonstrateresistance to temperatures up to 232℃pressures up to 114 barand are

inert to a wide spectrum of commercial chemicals.

▷ Outstanding protection against corrosion.

▷ Recommended in the chemical, pharmaceutical, electronic, pulp/paper, food

processing industries, as well as other vital manufacturing applications in which

corrosive chemicals

at high temperatures are frequently used.

▷ For lines carrying sulfuric acid, this is most frequently specified.

▷ It can resist thisacid at any concentration, including fuming oil.

VUE safety shield

▷ “See-Thru” shield that permits easy identification andinspection of all pipe joints,

including flanges, valves, threaded connections and expansion joints.

▷ Withstands temperatures up to 150℃ and pressures to 69 bar.

▷ It demonstrates a broad spectrum of chemical resistance, especially to most corrosive

chemicals and organic solvents.

Metal safety shield

▷ Galvanized steel, “304” stainless steel, “316” stainless steel

▷ It issufficiently heavy to withstand high pressures andalso has flexibility to permit

shaping

▷ Galvanized- Installed widely for water, oil andsteam applications

▷ It is vulnerable to corrosive attack and should not beused on lines carrying hazardous

chemicals

▷ Withstands temperatures up to 427℃ and pressures to 207 bar.

▷ SUS304 – Applications requiring mild corrosion resistance

Withstands temperatures up to 1454℃ and pressures to 207 bar.

▷ SUS3016 – To give superior resistance to pitting and to most types of corrosion,

making “316” suitable forapplications involving severe corrosive conditions.

Withstands temperatures up to 1454℃ and pressures to 207 bar.